–

in 2003…

HISTORY

ILMAG s.r.l Divisione Logistica is an Italian company specialized in the construction of machinery for the automation of paper and warehouse archives. The activity began in Dronero (CN) with few employees and with manual machinery for sheet metal working.

2001 – ILMAG s.a.s. is born from an idea by Paolo Pepe, who, after acquiring a ten-year experience in an important company in the sector, decides to apply his knowledge making products in a new way of total orientation to the needs of the customer

2009 – the perseverance in building quality products and the company flexibility met with success and thanks also to some important orders acquired on the foreign market, the company moves to the current plant of about 3,000 square meters in Busca (CN).

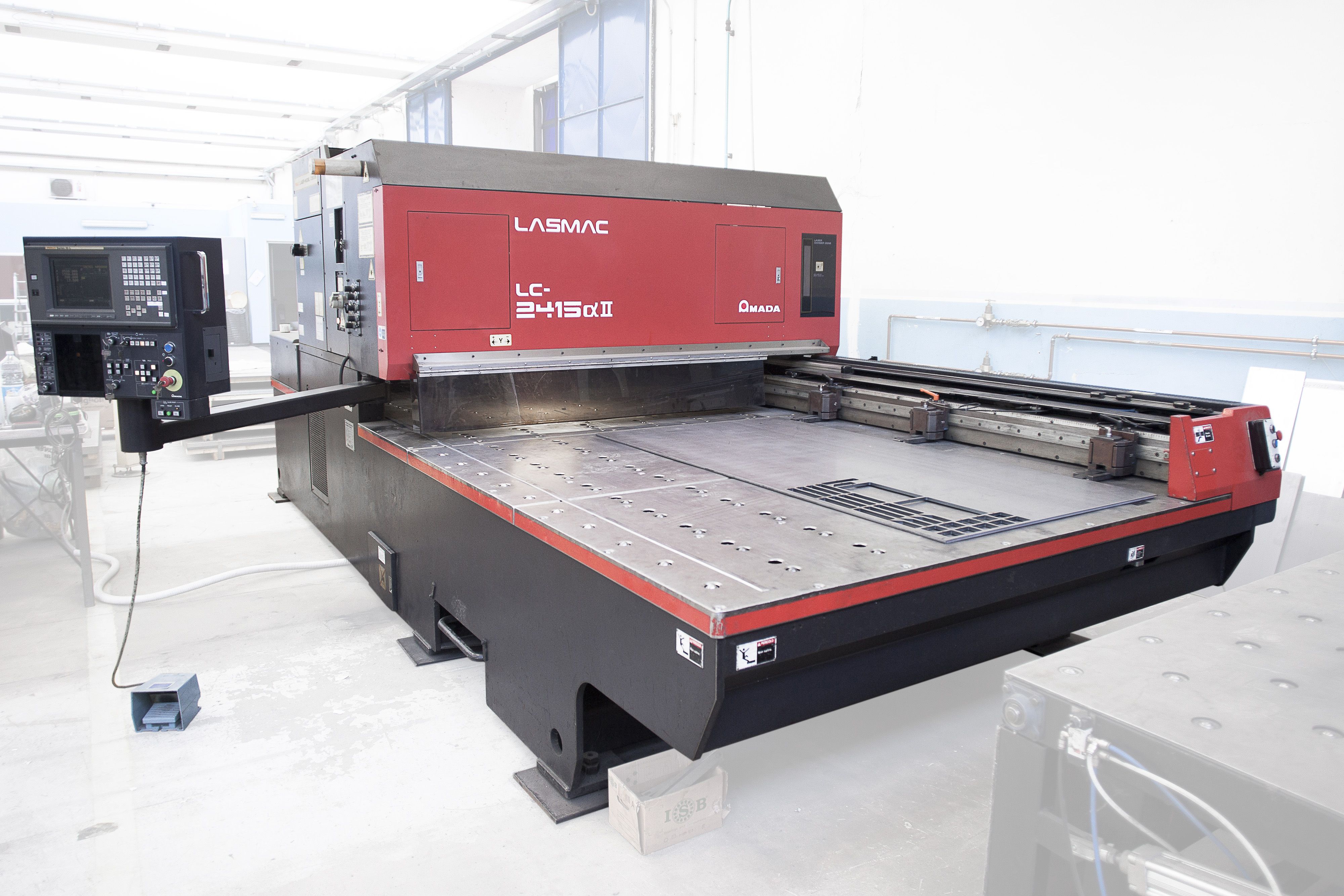

2010 – new automated machinery and sheet metal processing software are purchased. In the same year an internal electrical department was created, which deals with the design and production of all electrical panels and PLC programming

2011 – ILMAG Divisione Sistemi is a company that produces software for the management of ILMAG machines and deals with a continuous research and development of IT solutions integrated in the logistics field.

2013 – a production unit is opened in the previous factory in Dronero (CN) where a fully automated punching and cutting line is installed and a robotized sheet metal bending station.

2016 – ISO.MAG srl is created, a specialist company that follows post-sale all ILMAG installations and maintenance in Italy and for special systems also abroad.

2017 – ILMAG s.a.s is transformed into the current ILMAG s.r.l. Logistics Division.

Today we are one of the leading companies in the field of automation of warehouses and rotating archives, specialized in certain types of particular applications and we can guarantee a complete quality service from the design and production stage to the marketing, installation up to post sales technical support. All the various phases are managed and controlled internally by ILMAG in the various departments.

The sectors of application of the products are many and in little more than fifteen years of activity, we have a high calibre of references such as: Alenia, Agusta Westland, Bitron, Selex, Nestlè Group, Jabil, Novartis …

The company production is divided mainly into 3 groups: ARCHIVE – INDUSTRY – SPECIAL PROJECTS

Macro divisions of product categories in 2019:

–

in 2007…

Quality Policy

QUALITY POLICY

The improvement of quality standards, customer satisfaction and internal growth are fundamental aspects in order to compete successfully in today’s global market: ILMAG firmly believes in the growth opportunities that derive from the application of a quality management system

It will be periodically checked so that the effectiveness and efficiency performances remain high. The company provides adequate resources to mitigate the risks analyzed and identified for each individual process.

In this development path, the organization establishes the principles on which it wants to base its way of being a company:

- Satisfy the customer in the round, through the provision of appropriate products with punctuality, speed and flexibility and assistance in the definition phase of the requirements, to become his reference in the field of solutions for storage and warehouse.

- Position itself on the market as a supplier of innovative products, investing in the research and development of cutting-edge technical solutions.

- To operate in compliance with the laws, regulations and directives (national and EU) and all the requirements defined by the company with the interested parties.

- Sell products that comply with all technical and defect-free regulations.

- Ensure a high level of customer service.

- Minimize loses for “NON-QUALITY”.

- Introducing and keeping up-to-date management and surveillance procedures for the constant monitoring of personnel safety and for the interventions to be carried out in the case of non-compliant situations, anomalies or emergencies.

- Strengthen training and information activities, involving all operators to make them aware of their individual obligations and the importance of their every action to achieve the expected results and their responsibility in terms of quality and company safety.

- Identifying the dangers of the activities and assessing in advance the risks to the personnel, as far as they exist and for each new activity or process, to be able to adopt solutions that can prevent accidents and occupational diseases.

- Maintain work standards compliant with the legal prescriptions on occupational health and safety (Legislative Decree 81/08).

- Adopt methods to prevent pollution, save energy and optimize resource consumption.

- Pursue environmental, economic and social sustainability.

- Carry out an adequate consulting activity to contribute with its own technologies to maximize the value recognized in the product.

- Periodically review the risk assessment independently of changes that have occurred.

- Manage orders in an integrated way, starting from the needs of the customer and involving all the functions of the organization.

- Increase productivity to lower operating costs.

- To disseminate the content of this Policy, the objectives and the results of the monitoring of company processes to all the company’s people and stakeholders.

The Management undertakes to re-examine the adequacy of the quality management system and to provide indications on the corrections and improvements to be made to the structure of the system itself. It also verifies the achievement of the annual objectives and analyzes any deviations to make the organization evolve.

Busca, 9.th may 2023.

Certificates

ILMAG s.r.l. has been ISO 9001 certified since 2008 and is undergoing ISO 14001 certification.

All our products are CE marked.