Industry > R-MAG

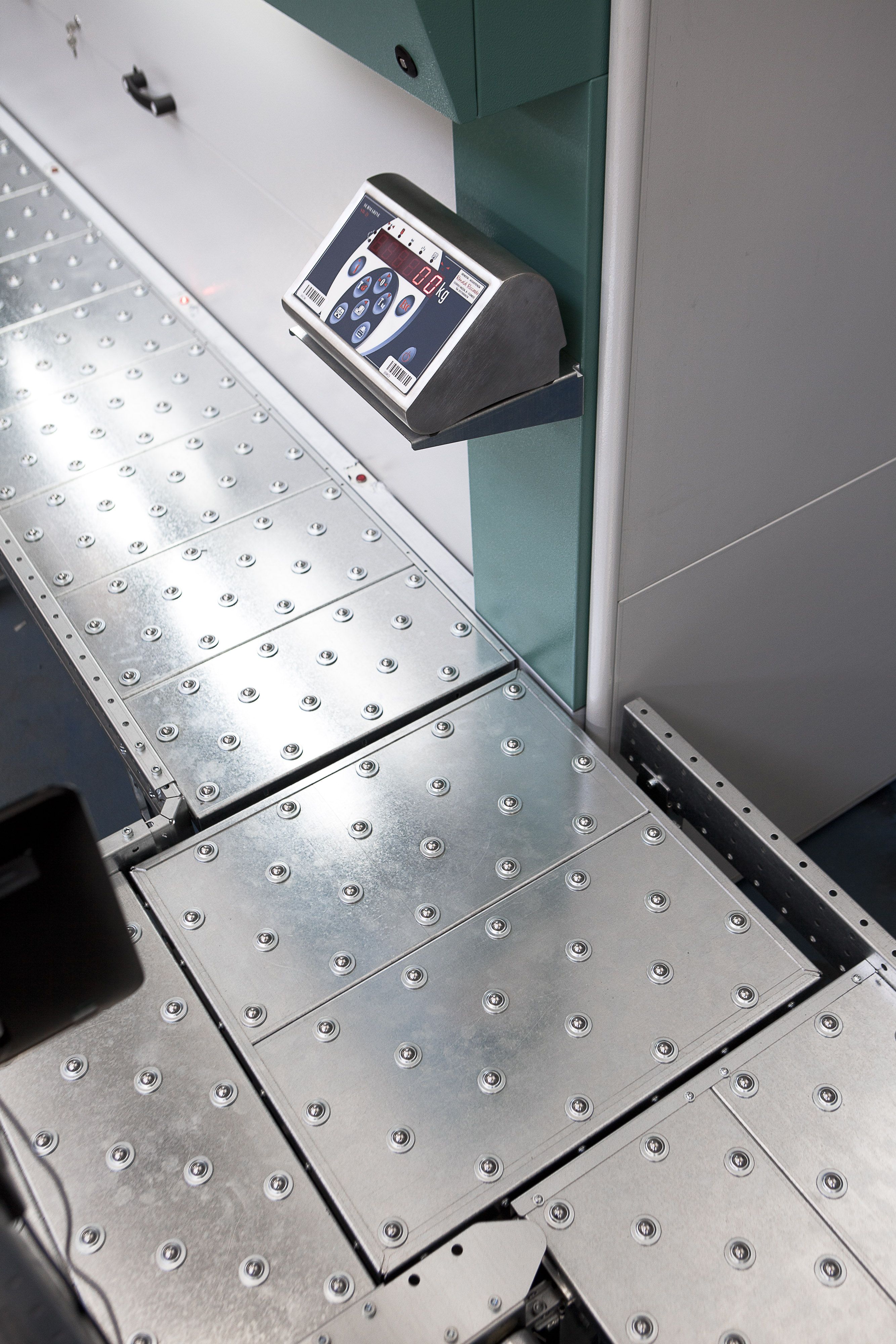

The R-MAG rotary table system allows space recovery by exploiting height. The use of rotating warehouses also allows a considerable reduction in the time required to search for the material and an ergonomic work station to protect the operator.

The R-MAG rotating table system is used in company warehouses, in the management of spare parts, in the storage of materials with particular characteristics and in all situations in which the order and certainty of the handling codes is important.

Features:

- PLC control (programmable logic controller)

- Vector inverter with STO safety function

- Frontal safety barrier over the whole working height

- Electronic components available on the market

- Automatic chain tensioning system

Optionals:

- motorized front shutter

- access control with password

- fire extinguishing system

- LED position indicator bar

Technical informations:

- Machine height between: 3 and 11 meters

- Standard machine width: 2728 – 3178 – 3364 mm

- Standard depth of the rotating table: 415 – 515 – 615 mm

- Rotating carrier capacity: 130 – 300 – 500 kg UD

Case Study

Telai Olagnero – Cuneo

Issue: the customer has obtained a significantly increase in orders and it is impossible to manage the procurement of small parts with the previous system.

Solution: with the R-MAG system, accompanied by the Logistic Expert software, a KANBAN system is implemented with direct connection to the small parts supplier. The preparation of the kits required for on-line assembly is carried out smoothly and the inventories are updated in real time both in the warehouse and at the supplier.